Rockwood

Well-known member

- May 5, 2021

- 6,431

- 8,276

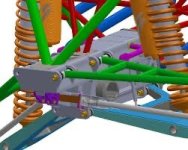

Newest issue, swaybar bolts are pulling out of the front diff bulkhead. Fix is to remove swaybar. Why are these mounted to the diff?

View attachment 88540

Looks like it’s in pink in the photo above. Not sure where the rest of that structure comes from, but that’s a super narrow sway bar. There’s going to be a LOT of force on that since the motion ratio is extremely high. With the bar that short and thick (hehe), the spring rate has to be astronomical.