Any day now... :biggrin:

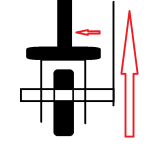

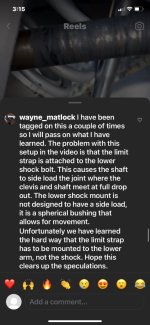

Unless the bolt was loose, this shouldn't happen. If the design is how I'm picturing it, I'd think the long bolt (which I'm pretty sure is smaller than the shock shaft) would fail way before the shaft. It really shouldn't see side load from the mounting point unless the bolt was loose and the whole clevis was rocking, or the pivot was binding.

EDIT: NM, it would see some side load since the clevis can rotate independent of the control arm mount.

View attachment 39108

Unless there's a bind in the mounts, or someone's using a limit strap, the only side load the shaft should see would be from springs bowing, but the clevis doesn't give/reduce any leverage in this case since the spring perch is about level with where the shaft screws onto the clevis. Possibly the valving, but again, this isn't really an issue with the clevis.

What material is used in the control armmount? If it's rubber, yeah, that would be a problem if the durometer is too high and it won't twist enough. Spherical shouldn't have any issues unless there's some whacky geometry where the arm rotates backwards and causes a bind.