- Thread starter

- #201

onanysunday

Well-known member

- May 7, 2021

- 3,832

- 3,499

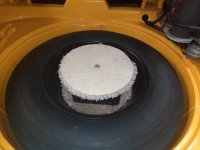

Had some Misty root beer left so why not. Then we can have Nick put a little panel that opens when he does all the leather work in the trunk. Now we have a spot for all of our spare tools, lug wrench, Jack wrench, etc. Plenty of room to wrap all that up and some nice tool bags and put in there. Probably have Nick put a little carpet in the bottom of it.