- Thread starter

- #881

onanysunday

Well-known member

- May 7, 2021

- 3,873

- 3,526

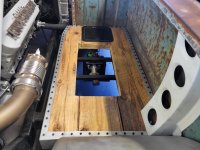

Well the struggle was real today for sure. I was one stressed out and pissed off dude. Put some wood shims under the motor mount so the back end could pivot down. Dropped the rear cradle down about 4 in and I am able to remove the wheels. Still a complete pain in the ass and not easy but really the only way to do it. At least I can get them off and on. So the process will be; number one wood shims under the motor mounts. Number two drain partial coolant and remove the rigid upper radiator hose. Number three disconnect the cold side intercooler charge pipes both sides. Number four remove all of the bolts holding the cradles to the frame in the back. The back pair of bolts underneath cannot go back in because the fuel tank will block them in. These are bolts I had added in addition to Rick's bulkhead mounts and we're really just Overkill anyway. Number five disconnect the sway bar once I have built that. Number 6 remove the four bolts from the front fuel tank mount to let the cradle drop away from the fuel tank. I will need some way to hold the front of the fuel tank up. Number 7 remove the rear cover plate and fuel cap to get to the frame to cradle bolts underneath it. It looks like I am also going to have to cut off the bulkhead fitting plate I just made and do another one. Those fittings are going to be in the way of those two bolts going through the frame and the cradle. Now I will have to be careful making my throttle cable and transmission cable flexible enough to not have to remove those. Same with any wiring harness. Make sure any fuel lines will flex as well. Probably something else I am not thinking of.