- Thread starter

- #861

onanysunday

Well-known member

- May 7, 2021

- 3,873

- 3,526

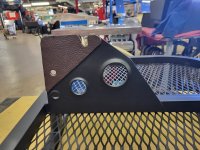

Phase one of operation rear removable storage rack. I love it when you think about something for several days or weeks and then it finally comes to you how to build it. Tomorrow when I dimple die the 8th inch main brackets I will make sure to use a torch. Last time I pressed it cold and it was a lot of pressure in the press.