Bobalos

Well-known member

- May 5, 2021

- 6,718

- 5,309

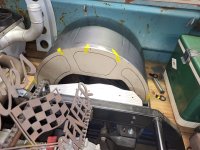

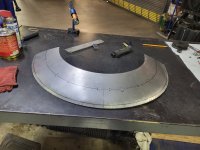

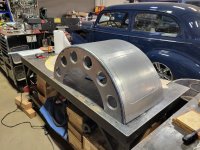

What would be really cool is if there was a way to make the wheel wells all Rusty and the same color/faded/beat up as the rest of the bed.

But.... at some point the old has to meet up with then new.....

But.... at some point the old has to meet up with then new.....

Last edited by a moderator: