- Thread starter

- #641

onanysunday

Well-known member

- May 7, 2021

- 3,873

- 3,526

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Sometimes less is more. There is so much amazing craftsmanship and detail in your build, that I don't think you need an over the top set of fenders.I like to dream about going crazy on this truck but it seems I always pull back. So I'm scrapping the flame idea. I keep going back to a simple three box bead roll design for each wheel well.

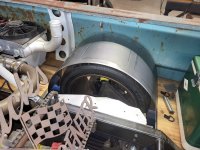

BE THE SHOW!!!! that's cool never seen that beforeI'm liking this style of gas cap. Some of these darn things are $500 which is nuts.

View attachment 89692