South Bay

Well-known member

- May 5, 2021

- 1,707

- 1,506

Love the way this is coming together . . .

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

It is all welded since that pic. I still need to pressure test it.

So, from the picture, and can't really tell, will you be able to remove the motor between those?Keep chopping away around those front tires. Still struggling how to put all this back together up front. On a fun note I got to bend my first piece of tubing today. That was fun.

View attachment 84682

View attachment 84683

View attachment 84684

View attachment 84685

View attachment 84686

View attachment 84687

View attachment 84688

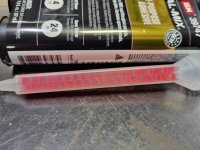

That whole rear roll bar section including the x-brace will have these four connectors in it. So it will be removable to get the motor in and out. You can see my pencil marks on the x-brace. I purposely made it too big so I need to cut it down to fit.So, from the picture, and can't really tell, will you be able to remove the motor between those?