Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SPEED Tech

- Thread starter Banshee2001

- Start date

ROBERT L

Moderator

- May 2, 2021

- 5,357

- 4,084

It will stay on topic.I'm going to start charging you guys for this information.

Busy today, might come back to this later, might not. Depends on whether or not this thread stays on topic. :classic_cool:

jginsandiego

New member

- May 5, 2021

- 290

- 290

Moving this from the old thread to this one

A few specs I asked the engineers at SSSS

1.75 to 1 hydraulic steering ratio

103 amp alternator belt driven external

There will be three key fobs unless you get the speed key you will get the normal key and a valet key the valet key will only allow a limited amount of horsepower kind of a training key like the Sea-Doo JetSki’s head for reasons you would need that such as letting a youngster or un experienced person drive the car

stock tire data straight off the side of the tires

on the 35 inch speed tire it says 35x9.5x15 eight ply 1020 pounds no DOT rating

on the 32 inch speed tire it says 32x9.5x15 eight ply load range D radio steel belted 1000 pounds no DOT rating

The front hub center in hole looks to be 5.625 inches in diameter

The lug nut size is 19 mm with a 12 mm thread

A few specs I asked the engineers at SSSS

1.75 to 1 hydraulic steering ratio

103 amp alternator belt driven external

There will be three key fobs unless you get the speed key you will get the normal key and a valet key the valet key will only allow a limited amount of horsepower kind of a training key like the Sea-Doo JetSki’s head for reasons you would need that such as letting a youngster or un experienced person drive the car

stock tire data straight off the side of the tires

on the 35 inch speed tire it says 35x9.5x15 eight ply 1020 pounds no DOT rating

on the 32 inch speed tire it says 32x9.5x15 eight ply load range D radio steel belted 1000 pounds no DOT rating

The front hub center in hole looks to be 5.625 inches in diameter

The lug nut size is 19 mm with a 12 mm thread

Rockwood

Well-known member

- May 5, 2021

- 6,433

- 8,280

The packaging on the transmission is pretty cool. No clue if this is common to SxSs in general, but using the the other gear-shafts to support the weakest spot of a gearstack (the middle) keeps them from flexing away from each other under load. FWD transaxles (or really any standard input/countershaft setup) will commonly shred the middle gears because the case/shafts flex and the gears lose mesh.I’ve got some pictures of the trans open along with a few showing a cutaway in the case to see it assembled.

Sean can you explain what we are looking at, and how it differs from the other brands? It would be awesome if you could show the same part in anther brand to compare the two. What areas did you guys have the greatest input in with Albins & Speed?

(Cheap Weddle Plug) For those who did not know. Weddle will be the authorized Speed Trans & Differential services center. So XYZ dealership’s oil change tech is not working on or rebuilding your Speed transmission.

View attachment 44627

View attachment 44628

View attachment 44629

View attachment 44630

View attachment 44631

Here is another small but important improvement made on the first pre-production cars and just a few months later when they were working on perfecting the shifter and trans gear selection. Look at how much better the shift linkage is on the trans. That’s more then just a lever. They had to redesign the shaft too.

Last edited by a moderator:

jginsandiego

New member

- May 5, 2021

- 290

- 290

I wonder if they have a magnet on the drain plug or fill plug? I guess it’s something you could probably add if not included.

CampfiresNbrews

Well-known member

- May 5, 2021

- 615

- 766

Lord of the Dunes

Well-known member

- May 5, 2021

- 1,864

- 1,508

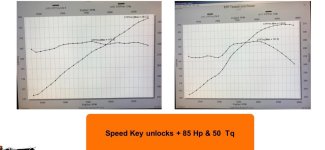

That's interesting, the text says it made 305 hp on race gas and it will make more on E85. I wish they would have tested it on E85, it would be nice to know that number.

One thing I never quite understood was how the ECU reacted to the ethanol %. Does it stay at the 225 hp tune at anything below E85, or does it ramp up the boost and timing in between E10 and E85? Would it make 275 hp at E75?

One thing I never quite understood was how the ECU reacted to the ethanol %. Does it stay at the 225 hp tune at anything below E85, or does it ramp up the boost and timing in between E10 and E85? Would it make 275 hp at E75?

CampfiresNbrews

Well-known member

- May 5, 2021

- 615

- 766

@Lord of the Dunes I overheard someone asking RG that question (not e75 but a certain ratio of 91 and e-85) and his answer was yes. It would make the appropriate horsepower accordingly. So anywhere from 225-300hp.

CampfiresNbrews

Well-known member

- May 5, 2021

- 615

- 766

Did anyone get a picture of the trailing arm tabs off of the hand built Diablos? Wondering if it’s the same design as what he’s putting on the newer cars. Here’s the only picture I got from last year. Try zooming in you can see a top plate connecting both tabs together. I didn’t see that on his new design fix??

Last edited by a moderator:

Rockwood

Well-known member

- May 5, 2021

- 6,433

- 8,280

0.5* of bumpsteer ~ just under 0.4" with a 35" tire for those who don't see things in radians. :biggrin:Here’s some info on the steering system and the changes made during development.

For those those who might not know, the steering is hydraulic vs electric like all the other UTV’s. I like features of both electric & hydraulic. They both have advantages. Electric is simple and compact. But it’s proven to be not as durable as hydraulic. I had one time where my electric steering was shocked and it jerked the wheel from my hand and wanted to pull hard left. After disconnecting the power it reset, but I was nervous the rest of that days Baja trip. I feel like a steering dampener should be used in conjunction with electric steering, as it can protect and absorb the shock sent through the rack, u-joints and motor. I do like that with the switch if a key to accessory you can have steering and not have the engine running,. Can’t do that with Hydraulic. Or if the electric steering fails you can have true manual vs trying to steer a failed hydraulic pump. Done that also in a class 10 car. Horrible! Now I like the feel of hydraulic better. The Ram internal or external acts as a shock protecting other components. Botton line hydraulic has proven to be much stronger.

Here is a original drawing of the of the hydraulic rack.

View attachment 44972

Like the front suspension arms and sway-bar the steering rack also mounts to the front bulkhead.

View attachment 44973

During testing in the small washboard Robby was feeling a slight chatter. They tested different pumps and servo’s and it did not change anything. Eventually they consulted with guys like Howe, Lee PS and each had their thoughts. Some valid, but did not cure the issue. One thing I guess they agreed on was using more hard line in the system. Here are some pictures of the hard lines ran down the middle of the chassis. Flex hose would still be used at the rack, servo & pump. Here is pictures from the Sand Show showing the PS hard lines. They are nicely clamped to welded tabs on the chassis.

View attachment 44974

View attachment 44975

Here is a picture showing the servo under the front hood.

View attachment 44976

But after adding more hard lines the chatter continued. It was eventually pinpointed to the rack itself. They found out that the rack ends were flexing causing the feed back, but only in the small stuff. Big bumps it was not felt. They decided to bolt & weld a plate to both ends of the rack to tie both sides together. This solved the issue. Here is the test plate welded to the rack.

View attachment 44977

Robby mentioned that mounting the rack where and how they did off the bulkhead painted them in a corner as if they were to build a different rack or increase the size, it’s not going to fit, and that would create having to redesign the bulkhead. So they had to figure out how to solve the problem within the box. What they came up with was a really nice designed upper & lower plate that bolts to each end and bolts through using the tie rod bolt, tying both plates together. I think the fix actually is a great improvement that makes the system only stronger & better.

Here is the lower plate. If you look close you will see the small Allen bolts attaching the end piece to the plate. Then you see the two flush nutserts that the tie rod bolt uses and supports the upper & lower plates together.

View attachment 44978

This angles from the upside down car at the show.

View attachment 44980

Here is the upper plate. It’s hard to see all of it. You can see the bolt head for the tie rod and that connects to the lower plate.

View attachment 44979

Here is a picture of how the tie rod attaches to the spindle upright. All in double shear.

(If you look close at the center of the stub axle you will see a zerk fitting. That’s to be able to grease the CV joint.)

View attachment 44981

Not pictured is a plate that will bolt on the hub face. This plate will be a stub axle nut lock, so no cotter keys are needed.

Another first for the UTV and really in the off road industry is a collapsible steering shaft. Robby design this after Max was in a pretty serious crash in Baja in a XX. Robby saw first hand how the steering wheel & shaft can push back into the drivers chest. In this photo you can see the steering shaft and where the internal splines are.

View attachment 44983

I don’t have a picture of the pump, but it mounts on the right side of the engine and is powered by the serpentine belt. If anyone has a picture please share.

There's a lot riding on that front stressed diff though. Engineers love making multiple uses out of a part, but sometimes this can backfire. Lots of pocketing and gussets on it, so the case it definitely stiff, but that's a lot of FEA time. Did Robby's mule have the cast front bulkhead in it for all of testing?

The wastegate looks effectively closed after 8,000rpm. I don't think there's much more in a tune aftermarket wise. E85 is oxygen bearing, so you'll get a little more "airflow" from the fuel, but I wouldn't expect much more than displayed here power wise, especially if it's the exhaust side that's impeding performance on the turbo.

Is there bracing to support the turbo? Even so, bracing is hard to get right expansion wise, and that long manifold going straight out like that is going to be under a lot of stress. I get the reasoning putting the turbo behind the axle centerline (patented even! :biggrin: ), but is the juice worth the squeeze?

How it should be. The arms are interesting with the shock pocketed in the kink. Wonder what they did inside of the arm to beef it up since there's a lot of stress in that area. Trailing arms are loooong and any side loads lever everything ahead of it. :biggrin:Did anyone get a picture of the trailing arm tabs off of the hand built Diablos? Wondering if it’s the same design as what he’s putting on the newer cars. Here’s the only picture I got from last year. Try zooming in you can see a top plate connecting both tabs together. I didn’t see that on his new design fix??

View attachment 44990

View attachment 44991

Sand Shark

Well-known member

- May 5, 2021

- 4,774

- 5,208

I wonder if you can get a race gas tune and ditch the E85 with the Speed Key.This is exactly how I understood it too. You need to have the Speed Key activated, and the flex fuel sensor will adjust the tune mapping based on ethanol measured.

Regarding LOTD question about race fuel. Early on in engine testing James Lin was testing & playing with mapping in the stock tune parameters. He tried using race gas and it was said he was seeing 250-260hp in the stock tune. Then when he tried it in the Speed Key parameters he got over 300 on race gas. It’s been said the lowered Bandit they run around the shop track is at 350hp on VP ethanol.

From what it was said along time ago the primary reason for using Ethanol was that was the only fuel that’s capable of getting them to 300hp and be a EPA legal fuel. Obviously it burns cooler, but they could never get through CARB with a race fuel tune.

Rockwood

Well-known member

- May 5, 2021

- 6,433

- 8,280

E85 would be better most likely, other than the monkey business with water and actual mixing percentages. There's a flex fuel sensor right?I wonder if you can get a race gas tune and ditch the E85 with the Speed Key.

Sand Shark

Well-known member

- May 5, 2021

- 4,774

- 5,208

I would assume there is a flex fuel sensor.E85 would be better most likely, other than the monkey business with water and actual mixing percentages. There's a flex fuel sensor right?

CampfiresNbrews

Well-known member

- May 5, 2021

- 615

- 766

I’d like to see where if any bracing is for the turbo as well. I get he added some pretty thick flanges to where it mounts to the engine but what’s supporting all that weight out there?0.5* of bumpsteer ~ just under 0.4" with a 35" tire for those who don't see things in radians. :biggrin:

There's a lot riding on that front stressed diff though. Engineers love making multiple uses out of a part, but sometimes this can backfire. Lots of pocketing and gussets on it, so the case it definitely stiff, but that's a lot of FEA time. Did Robby's mule have the cast front bulkhead in it for all of testing?

The wastegate looks effectively closed after 8,000rpm. I don't think there's much more in a tune aftermarket wise. E85 is oxygen bearing, so you'll get a little more "airflow" from the fuel, but I wouldn't expect much more than displayed here power wise, especially if it's the exhaust side that's impeding performance on the turbo.

Is there bracing to support the turbo? Even so, bracing is hard to get right expansion wise, and that long manifold going straight out like that is going to be under a lot of stress. I get the reasoning putting the turbo behind the axle centerline (patented even! :biggrin: ), but is the juice worth the squeeze?

How it should be. The arms are interesting with the shock pocketed in the kink. Wonder what they did inside of the arm to beef it up since there's a lot of stress in that area. Trailing arms are loooong and any side loads lever everything ahead of it. :biggrin:

Also regarding the arms and where the shock mounts, it has a sleeve built inside of them.

Last edited by a moderator:

Rockwood

Well-known member

- May 5, 2021

- 6,433

- 8,280

Yeah. Usually fabricated manifolds like that crack in the runners somewhere, not the flange (those just warp and leak).I’d like to see where if any bracing is for the turbo as well. I get he added some pretty thick flanges to where it mounts to the engine but what’s supporting all that weight out there?

Also regarding the arms and where the shock mounts, it has a sleeve built inside of them. View attachment 45044

Was more talking about how they reinforced the entire kink. I see evidence of tabs inside welded into it, but the kink itself presents problems since the wheel mounting surface isn't in line with the suspension mounts. Whenever the vehicle hits a bump, the tire will want to yank backwards and that force will be concentrated on the kink in the arm.

The arm itself looks beefy and I doubt it'll fail, just interesting to see how it was done.

CampfiresNbrews

Well-known member

- May 5, 2021

- 615

- 766

Interesting. Possible I guess. But did the Ac xx have issues? Looks to have the same general design. The insides of the Speed arms do have a lot of bridge A framed supports inside. Not sure how it’s layed out at that kink point?Yeah. Usually fabricated manifolds like that crack in the runners somewhere, not the flange (those just warp and leak).

Was more talking about how they reinforced the entire kink. I see evidence of tabs inside welded into it, but the kink itself presents problems since the wheel mounting surface isn't in line with the suspension mounts. Whenever the vehicle hits a bump, the tire will want to yank backwards and that force will be concentrated on the kink in the arm.

The arm itself looks beefy and I doubt it'll fail, just interesting to see how it was done.

Rockwood

Well-known member

- May 5, 2021

- 6,433

- 8,280

Yeah, maybe. The Speed UTV inboarded the pivots (I assume to drop roll center) so it puts the tire farther outside of the outer pivot.Interesting. Possible I guess. But did the Ac xx have issues? Looks to have the same general design. The insides of the Speed arms do have a lot of bridge A framed supports inside. Not sure how it’s layed out at that kink point?View attachment 45050

View attachment 45050

View attachment 44990

Like I said: I doubt the arm itself will fail or have issues, just interesting to see how it's done.

Last edited by a moderator: