rivermobster

Well-known member

- May 5, 2021

- 2,228

- 1,922

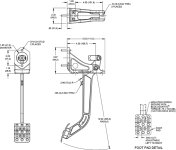

You doing ALL your wiring on paper first??

Yeah, it takes a huge amount of time, but it So much easier when you have a blueprint (wiring diagram) to build from.

Yeah, it takes a huge amount of time, but it So much easier when you have a blueprint (wiring diagram) to build from.