- Thread starter

- #801

onanysunday

Well-known member

- May 7, 2021

- 3,873

- 3,526

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

I can stand behind the tailgate and easily reach the fill. Yes fuel could run down on the wood if it splashes out. I might have to carry something as a precaution to keep that protected.Are you going to get in the bed when you are filling it up?

Can you stick the nozzle down far enough that it clicks off when it's full?

If it over flows, it's going to run down that piece and across the wood and run out between it and the tailgate.

Just thinking.....

Cool idea. Then the cap sits inside the box.Or maybe on the top a big one like on the bottom? it would roughly be the same dimensions.

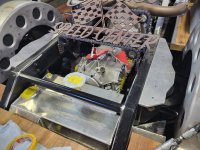

Ya those came from Rick Dobbertin and the mounts for the upper Vette a arms. Yesterday I actually had these flipped left and right making the top smooth. So I have been thinking about putting the milled grooves down and out of sight. They would just be flat and smooth and I would probably paint them bronze. Although black like the frame might look good. I will have to respray the top of all of the frame rails with the same rustoleum black.whatever these alum plates are is what throws it off for me, they don't fit/match the rest of the fabrication they say 1990 billet

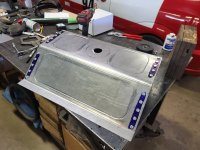

View attachment 98938

That's crazy over the top !. Dude probably has the rear view mirror on the motor !.

Here are a couple more photos. The wheels have a fair amount of clearance and I would have never guessed they would be so hard to get out. There is just so much offset to the inside on the 19x12 wheels and they hit the ball joint. I still don't think I would have wanted to narrow the cradle anymore. These pics show I could get them out with the upper arm and upper bolt removed from the airbag. Of course no axles. It would be extreme but it is possible to let the back of the trans/drivetrain drop down to remove them. It would be a PITA. Drain the coolant and remove upper hose. Remove motor mount bolts. Remove 14 bolts attaching the frame to the cradle. And I don't even know what else because I am still in fab stage. Maybe another option could be removing the upper and lower arms and moving the entire assembly in. That would depend on how much travel the CVs would have. I would have no problem making a jig to keep the axles from traveling too far down causing damage. I could also cut a stock axle 3" and install it. Then play with it and put an angle finder on the axle while removing the wheel. There has to be a way.