J Alper

Site Sponsor

- Apr 30, 2021

- 2,047

- 1,774

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

On wet sumps the oil level on a LS is almost to the top of the pan, if the motor is perfectly level with no stroked motor than you have about .500 away from the oil level, In a sand car i can not remember the time the motor was level, pretty much the crank is always in the oil, and adding a 4'' cranks makes it that much worse,What is the results with a dry sump?

J Alper -Stock engines kinda.... and really on older engines and not really true on LS's, the design of the pan and windage tray is pretty good even stock. And hardly ever on anything Hi-Po... at least in well designed blueprinted enginesOn wet sumps the oil level on a LS is almost to the top of the pan, if the motor is perfectly level with no stroked motor than you have about .500 away from the oil level, In a sand car i can not remember the time the motor was level, pretty much the crank is always in the oil, and adding a 4'' cranks makes it that much worse,

With a wet sump you gain the proper oil pressure and the HP does not get robbed from the oil splash,

Example: next time you are in a body of water slap your hand against the water, that is what the crank is doing,

Plus the oil being whipped will create air bubbles, and then the bearings and oil break down,

Great explanation. What would be the minimum estimated cost of an LS dry sump system just to maintain good oil pressure at the various dune angles?J Alper -Stock engines kinda.... and really on older engines and not really true on LS's, the design of the pan and windage tray is pretty good even stock. And hardly ever on anything Hi-Po... at least in well designed blueprinted engines

If you use a proper windage tray say from Improving oiling and fill properly a 1/2"of clearance to the oil is pretty good - using a crank wiper is even better - these issues are mostly non existent. you have to remember the rods on a stroker often have .060- .080 clearance from the block and the crank is spinning around in the closed skirted block which is the real issue with the LS - the Skirt causes windage - the air compresses and pushes against the rotating mass - the advantage is it actually pushes the oil away from the crank at speed. Its and old Ford design that Chevy adopted to allow the use of a light weight Aluminum block and still have side support for the mains - not a bad overall design the skirts are integral in making the block strong and even the pan is a structural member of the engine ( the reason so many fabricated pan LS engines lose the thrust main...)

the Motown designed LS Next - now Dart is basically a SBC bottom end with LS heads and does gain 30HP at higher RPM just by eliminating the windage. but thats only an iron block with splayed mains - they leak like old SBC's so not my choice ...

Dry sumps while way better in most cases controlling drops in oil pressure because the oil does not run away from the pick up at steep angles and under hard acceleration have never demonstrated more than about a 15HP gain on an LS - thats the consensus by the leader Dailey. Their numbers show that, and he attributes the HP gain mostly from the Vacuum effect of creating better ring sealing using the dry sumps scavenging. on Turbo engines you may see more HP gain, but again due to ring seal.. The dry sump pumps have to do more work than an internal LS pump (which is really efficient and draws virtually no HP) and draw far more HP doing it, so the net HP gain is essentially zero - and Daily has a patent on his pump that supposedly eliminated the foaming you get from other drysumps - drysump pumps always foam the oil - part of the reason that a decent LS dry sump requires 12-16 Qts or more of oil because you have to pass the oil through 3 or more screens on the tanks to eliminate foam. I like dry sumps for the reasons of oil control and ground clearance, but not because they make any real HP on an LS unless you are running a Max effort Sc or TT engine and even there you will be running a 5 or 6 stage pump and an external cog belt that requires maintenance and could break or get pushed off by sand - and thats really bad , so IMO if you want peace of mind that you will mostly always have good oil pressure and you want or need ground clearance and have room for a Huge tank spend the $$ and go Dry sump but don't do it to chase HP on a sand car

Drysumps are pretty complex you have a pan, pump, new balancer (likely) with cog belt drive for pump, a sump tank and a few of expensive hoses (need to handle vacuum)Great explanation. What would be the minimum estimated cost of an LS dry sump system just to maintain good oil pressure at the various dune angles?

I dont line the billet pans like the dailys, very showy, the standard Avaid, is easy to adjust the belt, just add a wash behind the bracket on the side,Great explanation. What would be the minimum estimated cost of an LS dry sump system just to maintain good oil pressure at the various dune angles?

$2500 is a nice deal for a basic system 3 stage - no turbos - but I would not use Chineseium Hoses and fittings - doing the math you will have over $1000 in hoses and fittings assuming you use non collapsable hoses - and I have done enough of these to know the costsI dont line the billet pans like the dailys, very showy, the standard Avaid, is easy to adjust the belt, just add a wash behind the bracket on the side,

- Balancer if you have a ATI will just need a Hub - $200

- ATI balancer supplied by us around $380

- Peterson tanks not my favorite are $800, Great tanks by Patterson is around $700 amazing tanks, used tanks on ebay, some very high end can even run as little to a $100

- need a remote oil filter housing $50-$150

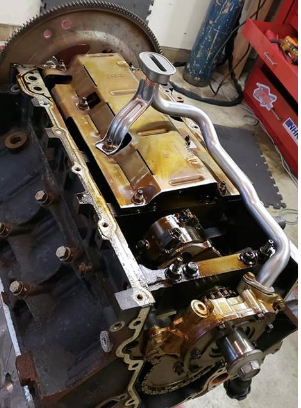

- oil pan $300-$400 new, have got a lot of used oil pans on ebay with scratches for $150

- New pump runs around $1300 with the LS bracket, and pulley with pulley guard, and oil pan gasket and timing belt

- Then run your hoses, about $400 in hoses and fittings

Typically a full system is around $2500.00 for a dry sump,

Our wet sump with a G8 oil pan kit is about $400, then a windage tray from mast $90, then improved baffle is $200, oil pump with mods $200, oil filter remote block improved racing $170 remote filter block $50-150

About $1000 difference, but not apples to apples, bearing life will be way longer on a dry sump, plus on my NA motor, the throttle response is way faster and you can feel the HP like a cam-swap,

My personal feeling, the only thing that will help a wet sump is letting the motor rest. so the air can dissipate. or super deep sump like truck pans, but the truck pans sit way low, probably going to sit below the trans,If aeration is the problem maybe running a quart or so low would help ? As long as no drop in oil pressure

at least that what the first video seems to indicate it also seems that running the hill while pulling a wheeling would fill the back 2 cylinders with oil and really aerate the oil and could it cause other issues for oil control rings ?

What is your definition of a "Long period of time"?On the fitting, like Alex Stated, i have use the Ractronix, and kind of a one use deal, they are not easy to get off and on, I have some XRP fittings that are from 2006 and still work like the day i got them,

The Daileys pumps are more efficient with using aluminm lobes, but the ones we service, the lobes do not take much to get beat up, the Daileys is more compact and will need more servicing the lobes to keep the efficiency level higher, They also use a smaller pulley, so less belt contact, I replace the Daileys pulleys ever other year or every year,

The Aviaid is hard to spell, but using basically SBC or BBC gears inside the pump stacked 3-5 times, basically like a old school oil pump inside, Service on those pumps are pretty straight forward, you have the Suction side called the scavenge side, and then the oil pump gears for the pump side, you will change the small seal between the scavenge a pressure plate, and then change the shaft seal on the outside, they have small o-rings between the stages, but i use a little bit of clear silicone for the pumps being used in the desert, super quick and easy to take these pumps apart, and you can always send them to us or the manufacture,

Adjusting the oil pressure can be done by adjusting the relief or also adjusting the pulley size, pulley size will help with oil pressure at idle. the pressure relief got something in it one trip and i simply unscrewed the top and sprayed it out with brake cleaner, when this happens on a normal LS wet sump pump the pan will have to be dropped,

These pumps can make some pressure when my relief got stuck it was 150lbs at idle,

I think for most the hard part is mounting a tank, this can be tricky, custom tanks can be square or multiple shapes,

If you want to run Hard for a Long period of time, the Dry Sump System is a great way to go,

There is just not a lot of options anymore, The first series G8 I would stay away from you need the LS3 G8 not the 2010 below, the new G8 Mid Sump 8 Quart pan is the one everyone uses now, I really do not like the LS2 Front Sump pan, With Dedicated Rear Sump or Dedicated Front sump pans you will have more oil crank whipping, The SS Camaro pan for the LS3 with a Mid Sump is my go to pan, cam out in 2013 and up,You're funny Alper, years ago before the site crash there was a discussion regarding the best LS pan. I mentioned I use a G8 pan because it held 8 qts, you said that pan is no good and to use some other pan you sell instead. Now you are recommending the G8 pan. ???

Except for the F-body pans that a lot of folks run because of clearance:J Alper -Stock engines kinda.... and really on older engines and not really true on LS's, the design of the pan and windage tray is pretty good even stock. And hardly ever on anything Hi-Po... at least in well designed blueprinted engines

If you use a proper windage tray say from Improving oiling and fill properly a 1/2"of clearance to the oil is pretty good - using a crank wiper is even better - these issues are mostly non existent. you have to remember the rods on a stroker often have .060- .080 clearance from the block and the crank is spinning around in the closed skirted block which is the real issue with the LS - the Skirt causes windage - the air compresses and pushes against the rotating mass - the advantage is it actually pushes the oil away from the crank at speed. Its and old Ford design that Chevy adopted to allow the use of a light weight Aluminum block and still have side support for the mains - not a bad overall design the skirts are integral in making the block strong and even the pan is a structural member of the engine ( the reason so many fabricated pan LS engines lose the thrust main...)

the Motown designed LS Next - now Dart is basically a SBC bottom end with LS heads and does gain 30HP at higher RPM just by eliminating the windage. but thats only an iron block with splayed mains - they leak like old SBC's so not my choice ...

Dry sumps while way better in most cases controlling drops in oil pressure because the oil does not run away from the pick up at steep angles and under hard acceleration have never demonstrated more than about a 15HP gain on an LS - thats the consensus by the leader Dailey. Their numbers show that, and he attributes the HP gain mostly from the Vacuum effect of creating better ring sealing using the dry sumps scavenging. on Turbo engines you may see more HP gain, but again due to ring seal.. The dry sump pumps have to do more work than an internal LS pump (which is really efficient and draws virtually no HP) and draw far more HP doing it, so the net HP gain is essentially zero - and Daily has a patent on his pump that supposedly eliminated the foaming you get from other drysumps - drysump pumps always foam the oil - part of the reason that a decent LS dry sump requires 12-16 Qts or more of oil because you have to pass the oil through 3 or more screens on the tanks to eliminate foam. I like dry sumps for the reasons of oil control and ground clearance, but not because they make any real HP on an LS unless you are running a Max effort Sc or TT engine and even there you will be running a 5 or 6 stage pump and an external cog belt that requires maintenance and could break or get pushed off by sand - and thats really bad , so IMO if you want peace of mind that you will mostly always have good oil pressure and you want or need ground clearance and have room for a Huge tank spend the $$ and go Dry sump but don't do it to chase HP on a sand car