Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Summer upgrades that got a little out hand...1.5 year upgrade

- Thread starter Hammond_fab

- Start date

- Thread starter

- #22

Hammond_fab

Active member

- May 9, 2021

- 95

- 119

Wastegates probably should have been a little bit larger. At low boost it still managed to make a pound more of boost than what was really wanted. That could have been a result of the springs just not being exact too.Nice wastegate priority on the secondary. Didn’t even notice it was a twin scroll, nicely done.

- Thread starter

- #23

Hammond_fab

Active member

- May 9, 2021

- 95

- 119

The car is currently running. But its currently held together with a lot of zip ties. I didn't want to miss any more trips.I went down the same rabbit hole, several times now. It works out in the end. You're doing some very nice fab work, keep it up and continue to update the forum on your progress. This is an awesome build thread for sure.

- Thread starter

- #24

Hammond_fab

Active member

- May 9, 2021

- 95

- 119

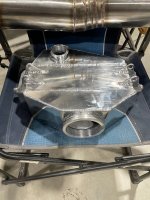

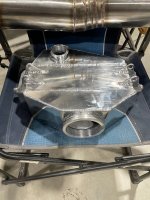

I had to shorten the charge side of the turbo about an 1". I then chucked the V-band portion into the lathe and trued it back up. I also sanded the throttle body to get the angle closer to lining up with the intercooler. I welded the other side of the motion race works quick seal clamps to the mutilated throttle body. I couldn't find a picture of that.

- Thread starter

- #25

Hammond_fab

Active member

- May 9, 2021

- 95

- 119

Rockwood

Well-known member

- May 5, 2021

- 6,325

- 8,138

Was it slowly creeping on the top end, or rock solid, just a pound high? Creep would be too small, plateau of boost, yeah, where you put the vacuum lines, etc, etc, makes a difference.Wastegates probably should have been a little bit larger. At low boost it still managed to make a pound more of boost than what was really wanted. That could have been a result of the springs just not being exact too.

If you have the reference line on the manifold, moving it to the compressor outlet will drop it by a pound or 2…

But I assume you’re not unwelcome to moar horsetorques :biggrin:

- Thread starter

- #27

Hammond_fab

Active member

- May 9, 2021

- 95

- 119

I have my boost reference on the charger side of the intercooler. It peaked at 7.2 pounds with 6 psi springs in them. I wasn’t too worried about it. One day I will flip the switch to see how the high boost works which should be 50% duty cycle.Was it slowly creeping on the top end, or rock solid, just a pound high? Creep would be too small, plateau of boost, yeah, where you put the vacuum lines, etc, etc, makes a difference.

If you have the reference line on the manifold, moving it to the compressor outlet will drop it by a pound or 2…

But I assume you’re not unwelcome to moar horsetorques :biggrin:

the horse torques are much appreciated

- Thread starter

- #29

Hammond_fab

Active member

- May 9, 2021

- 95

- 119

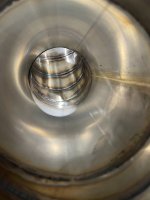

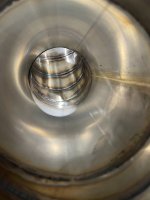

The next task was figuring out how I was going to build the intake and exhaust downpipe/uppine. I ended up using 5" 304 stainless steel. Mandrel bent tubes of that size are hard to find and very expensive when you do find them. I used my bandsaw to make all of the pie cuts...very inconsistent and it ovaled the tube in the clamps.

Here I was thinking I was going to totally kick ass on the welds with all of the prep and purging

; but ended up burning it pretty good. Good thing the stainless still polished out.

; but ended up burning it pretty good. Good thing the stainless still polished out.

Here I was thinking I was going to totally kick ass on the welds with all of the prep and purging

; but ended up burning it pretty good. Good thing the stainless still polished out.

; but ended up burning it pretty good. Good thing the stainless still polished out.

BONES

Well-known member

- May 5, 2021

- 526

- 522

You have exhaust that the Cummins guys can be jealous of. That’s rad on a sand car, I bet it gets some attention.

Rockwood

Well-known member

- May 5, 2021

- 6,325

- 8,138

Beautiful work.

- Thread starter

- #32

Hammond_fab

Active member

- May 9, 2021

- 95

- 119

The exhaust/down pipe is inspired by those large caterpiller backhoes.You have exhaust that the Cummins guys can be jealous of. That’s rad on a sand car, I bet it gets some attention.

- Thread starter

- #33

Hammond_fab

Active member

- May 9, 2021

- 95

- 119

At this point it was time to tear the engine down to gap the rings. The original top ring gap was .014"...That's probably why these things are temperamental when the get too hot. I calculated the ring gap to a very safe and rather unnecessary .026" for the top ring and .028" for the bottom. I didn't feel like dealing with the torque to yield head bolts and went with the ARP head studs. So, stock rods and pistons just with the ring gaps set for boosted applications...not how I would have preferred to do that; but that's what budgets hold us too.

Richard Holdener and Engine masters would be proud of it though.

Richard Holdener and Engine masters would be proud of it though.

Reece Pettersen

Well-known member

- May 6, 2021

- 335

- 444

Awesome work! Keep the progress photos coming.

Rockwood

Well-known member

- May 5, 2021

- 6,325

- 8,138

E85 or some sort of race fuel/mix?

Doonit

Active member

- May 6, 2021

- 199

- 138

Now you're just showing off. You can do it all, motor work, fab work etc.... Amazing work fun to watch.....

- Thread starter

- #37

Hammond_fab

Active member

- May 9, 2021

- 95

- 119

I run E85.E85 or some sort of race fuel/mix?

I’m running some flow balanced Bosch 210Ib injectors (They were cheap)

I run a magnafuel pump so far it’s been great for the cost.

- Thread starter

- #38

Hammond_fab

Active member

- May 9, 2021

- 95

- 119

Thank you! Where I bow out is the electrical. I just get everything mounted and plumbed and have my buddy wire it.Now you're just showing off. You can do it all, motor work, fab work etc.... Amazing work fun to watch.....

Rockwood

Well-known member

- May 5, 2021

- 6,325

- 8,138

chit’ll be fiiiiiiine. Just resist that dial-a-boom knob on the boost controller. :biggrin:I run E85.

I’m running some flow balanced Bosch 210Ib injectors (They were cheap)

I run a magnafuel pump so far it’s been great for the cost.

- Thread starter

- #40

Hammond_fab

Active member

- May 9, 2021

- 95

- 119

I haven’t flipped the boom switch on the controller yet so we should be good still.chit’ll be fiiiiiiine. Just resist that dial-a-boom knob on the boost controller. :biggrin:

should be about 12psi on high.