Rockwood

Well-known member

- May 5, 2021

- 6,258

- 8,064

Haven't really done much since the crash, but here's how she sits now:

The LM7 and 4L60E are waiting to drop in, but delays with parts combined with my complete lack of time to do anything means I didn't get it ready prior to Summer Jeeping.

But, if I'm gonna limp the 4.SLO though another season in the mountains, cooling needs addressing ASAP. Biggest issue with XJs is the mechanical fan does mostly okay for higher RPM operation, but doesn't flow chit at low RPM (where my Jeep spends a lot of time working hard). Since it's almost always towed somewhere (never towing) and you can always slow down a little, I switched to an e-fan for it. Biggest bummer with E-fans is most don't work very well, or need lots of amperage, or whatever. Enter the Volvo/Taurus fan, which some people have measured as much as 3,000CFM out of, and based on the gale-force winds that come out of it, I'd believe them. Problem is, it's yuuuuge and the fan clutch pulley is in the way.

Nice thing about the Volvo version is it's 2 speed (which will reduce electrical loads) and comes with a relay pack. Scored for $30 from the Gank a Part.

Now, for shoe-horning. To start with, belt routing was going to be a problem. The stock belt routing requires keeping the fan pulley:

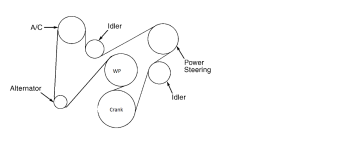

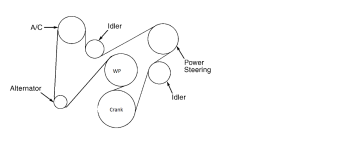

Or you won't be able to tension it. After some brainstorming, I came up with this:

This would ensure sufficient belt wrap and place the fan's motor (worst clearance) out of the belt's way. The problem is 97+ XJ's didn't come with the extra idler below the AC compressor to clear the thermostat housing, so back to the Gank A Part I went

Step one was to cut the existing bearing/pulley mount off. Step 2 was to modify the Alternator bracket to clear the belt:

The stud going through the hole where the grinder marks are will be omitted on re-installation. Even still, it still needed some extra clearance, so I formed it to the block by re-installing the bolt and smooshing it until it was against the block (yes, this engine is CRUSTY):

With belt routing out of the way, I got to work trimming the fan shroud:

I filled in the bottom of the shroud with 3003 aluminum sheetmetal I had lying around and riveted to the shroud (no pics). On top, I bent another piece of 3003 to fill in the 1/2" or so of void above the stock radiator core support.

Reinstalled, clearance to the engine is definitely tight, but in 500 miles of wheeling, hasn't touched at all. Amusingly, the stock 97+ XJ serpentine belt worked perfectly despite the radical change in routing.

Temps stay nice and frosty now at low speed. Like, I can watch the thermostat cycle no matter what I'm doing and where the AC is set, where before I always had an eye on the temps to keep it from boiling over. AC also blows colder than a well digger's ass. Climbing 7-10% grades in 2nd trying to wheeze that 4.SLO to maintain the speed limit does see some elevated temps (220*F vs 215*F in similar conditions previously). I have a week-long trip to Big Bear 9-13 and temps look to be in the mid/upper 80s at 7,000'+, so it'll be put to the test for sure.

The LM7 and 4L60E are waiting to drop in, but delays with parts combined with my complete lack of time to do anything means I didn't get it ready prior to Summer Jeeping.

But, if I'm gonna limp the 4.SLO though another season in the mountains, cooling needs addressing ASAP. Biggest issue with XJs is the mechanical fan does mostly okay for higher RPM operation, but doesn't flow chit at low RPM (where my Jeep spends a lot of time working hard). Since it's almost always towed somewhere (never towing) and you can always slow down a little, I switched to an e-fan for it. Biggest bummer with E-fans is most don't work very well, or need lots of amperage, or whatever. Enter the Volvo/Taurus fan, which some people have measured as much as 3,000CFM out of, and based on the gale-force winds that come out of it, I'd believe them. Problem is, it's yuuuuge and the fan clutch pulley is in the way.

Nice thing about the Volvo version is it's 2 speed (which will reduce electrical loads) and comes with a relay pack. Scored for $30 from the Gank a Part.

Now, for shoe-horning. To start with, belt routing was going to be a problem. The stock belt routing requires keeping the fan pulley:

Or you won't be able to tension it. After some brainstorming, I came up with this:

This would ensure sufficient belt wrap and place the fan's motor (worst clearance) out of the belt's way. The problem is 97+ XJ's didn't come with the extra idler below the AC compressor to clear the thermostat housing, so back to the Gank A Part I went

Step one was to cut the existing bearing/pulley mount off. Step 2 was to modify the Alternator bracket to clear the belt:

The stud going through the hole where the grinder marks are will be omitted on re-installation. Even still, it still needed some extra clearance, so I formed it to the block by re-installing the bolt and smooshing it until it was against the block (yes, this engine is CRUSTY):

With belt routing out of the way, I got to work trimming the fan shroud:

I filled in the bottom of the shroud with 3003 aluminum sheetmetal I had lying around and riveted to the shroud (no pics). On top, I bent another piece of 3003 to fill in the 1/2" or so of void above the stock radiator core support.

Reinstalled, clearance to the engine is definitely tight, but in 500 miles of wheeling, hasn't touched at all. Amusingly, the stock 97+ XJ serpentine belt worked perfectly despite the radical change in routing.

Temps stay nice and frosty now at low speed. Like, I can watch the thermostat cycle no matter what I'm doing and where the AC is set, where before I always had an eye on the temps to keep it from boiling over. AC also blows colder than a well digger's ass. Climbing 7-10% grades in 2nd trying to wheeze that 4.SLO to maintain the speed limit does see some elevated temps (220*F vs 215*F in similar conditions previously). I have a week-long trip to Big Bear 9-13 and temps look to be in the mid/upper 80s at 7,000'+, so it'll be put to the test for sure.