Sausage450r

Well-known member

- May 5, 2021

- 2,065

- 2,462

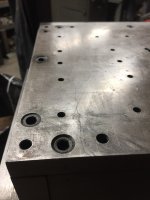

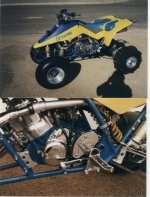

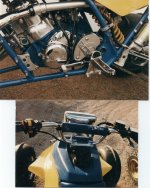

Are they not available? You want true water jacketed or just water injected? Jacketed headers are a pain in the azz. They are literally a header within a header. These ones are smoked. Stainles primaries and steel jacket, steel is nearly 80% compromised. I told him this will get him through the weekend.Would you be interested in building a set?