Hi!

Regarding the chain drive steering ratio:

Stock: 2.09” displacement per 1 wheel turn = 2.09 (disp/turn) lets call this (S)

Aftermarket: 2.00” displacement per 3/4 wheel turn or 2.00/.75 = 2.667 (disp/turn) lets call this (A)

The aftermarket system needs to “slow down” (A/S) = 1.276 times to match the stock turn ratio. That is the sprocket teeth ratio needed in the chain drive system.

The closest you get with a set of sprockets could be 18 teeth and 23 teeth, or a (23/18) 1.277 ratio where the small sprocket is at the servo motor and the large sprocket is at the rack.

Also need to make sure the idler pulley doesn’t crash the two chains together. Here’s a CAD sketch that helps determine whatever length between sprockets will be able to support an even number of links without letting the chains clash at the idler. I measured my 530 chain, and got .625” per link. Or 1.25 every two links. (Couldn’t find the actual spec anywhere but good start) Here is an example of dimensions that would work with 124 links, or 77.5” of chain (for one set of sprockets). Once you get closer to knowing the sprocket-sprocket center length, I can update the dimensions. Also the idler can be the smallest amount of teeth that will fit over whatever axle/bearing setup you have.

View attachment 67039

Sprocket Specialists is where I get custom made sprockets. Good option if you need something thats not off-the-shelf.

https://sprocketspecialists.com

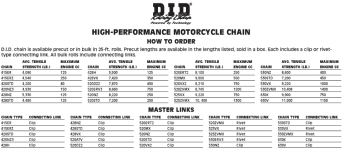

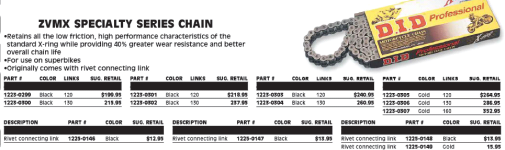

DID 530 ZVMX has 10,408 Avg Tensile Strength. This is a greased o-ring chain so wouldn’t ever need lube it. This is what I use on my King Car. This ones gold but they have other options.

https://www.amazon.com/D-I-D-530ZVMXG-160L-Super-Street-X-Ring/dp/B077BC3MRV

View attachment 67040

View attachment 67041

I am curious what the max output torque is on the electric steering unit. We can make dead sure a set of two 530 chains can handle it.

-Nf