Just curious what an ideal temperature swing would be between the radiator inlet and outlet. My scenario is a LS1, CBR aluminum radiator with two 12” SPAL fans. Delphi computer cuts the fans in at 201 and out at 185 if I recall correctly. With the engine idling in 90° ambient air, my upper radiator fitting reads 205ish with an infrared temp gun (aluminum AN fittings upper and lower) while the lower reads about 180°. My fans run constantly once the engine reaches operating temperature in this scenario. This has lead to the occasional burned up fan relay. For reference the computer did have triggers for the fans to come on separately, but they have since both been wired together on the cooler circuit. The temp gun on the cylinder heads reads about 187~190.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Temperature difference between upper and lower radiator outlets

- Thread starter Adam G

- Start date

I’ve never quite understood why people make the On-off ranges so wide. The goal is tight temp control, not a 20-30degree range.

Trying to cool the water from 200 to 185 takes a lot of air. That’s why the fans run so hard. Might consider putting the trigger range tighter together, like 205-200.

Your original question on what is a good delta T for inlet depends a bit on the conditions. 20deg delta is really good. Is that with the fans on? Or just after they shut off? Where the water temp sensor is located has an effect as well. (Note: if you are trying to get the water temp in the cylinder head to 185 and your radiator outlet is 180… that’s only a 5 degree delta inside the head)

Trying to cool the water from 200 to 185 takes a lot of air. That’s why the fans run so hard. Might consider putting the trigger range tighter together, like 205-200.

Your original question on what is a good delta T for inlet depends a bit on the conditions. 20deg delta is really good. Is that with the fans on? Or just after they shut off? Where the water temp sensor is located has an effect as well. (Note: if you are trying to get the water temp in the cylinder head to 185 and your radiator outlet is 180… that’s only a 5 degree delta inside the head)

Sandkist

Well-known member

- May 6, 2021

- 2,959

- 705

With or without a tstat?

Kraut_n_Rice

Site Sponsor

- May 9, 2021

- 3,410

- 2,695

Tighter temp ranges makes the circuit cycle more. That is what kills the components. on/off/on/off/.....I’ve never quite understood why people make the On-off ranges so wide. The goal is tight temp control, not a 20-30degree range.

Trying to cool the water from 200 to 185 takes a lot of air. That’s why the fans run so hard. Might consider putting the trigger range tighter together, like 205-200.

Your original question on what is a good delta T for inlet depends a bit on the conditions. 20deg delta is really good. Is that with the fans on? Or just after they shut off? Where the water temp sensor is located has an effect as well. (Note: if you are trying to get the water temp in the cylinder head to 185 and your radiator outlet is 180… that’s only a 5 degree delta inside the head)

- Thread starter

- #5

I don’t have any info on who tuned the computer, or who even built the engine. LS1 block with 243 heads, so I know something not stock compared to the 2000 Camaro the serial number comes back to. I think HP Tuners said the Delphi was from a S-10 too. Closing the temp gap might be a good tweak with the software.I’ve never quite understood why people make the On-off ranges so wide. The goal is tight temp control, not a 20-30degree range.

Trying to cool the water from 200 to 185 takes a lot of air. That’s why the fans run so hard. Might consider putting the trigger range tighter together, like 205-200.

Your original question on what is a good delta T for inlet depends a bit on the conditions. 20deg delta is really good. Is that with the fans on? Or just after they shut off? Where the water temp sensor is located has an effect as well. (Note: if you are trying to get the water temp in the cylinder head to 185 and your radiator outlet is 180… that’s only a 5 degree delta inside the head)

The ~20° delta was with the fans running (they don’t shut off once temp is reached) and it was similar right before the fans came on.

- Thread starter

- #6

I actually don’t know if it has a thermometer in the housing or not.With or without a tstat?

FOG

Well-known member

- May 11, 2021

- 1,915

- 2,397

Completely agree with this. Surge current is not nice to electrical components like fans, relays and etc. It’s better to let the fans run for the entire ride than to cycle them on and off several times.Tighter temp ranges makes the circuit cycle more. That is what kills the components. on/off/on/off/.....

- Thread starter

- #8

Wire (gauge), connectors and relays were all upgraded before last season and I went through two relays. The fans are new, legit brushless SPAL fans, I double checked and they’re actually 16”. I’m not feeling additional heat from the wiring or connectors, but the damn relays keep melting a pin. I do dune hard with plenty of pepper and as few breaks as I can manage. I have a windshield and a radiator that is pretty low, so maybe the cooling system is just inadequate?Completely agree with this. Surge current is not nice to electrical components like fans, relays and etc. It’s better to let the fans run for the entire ride than to cycle them on and off several times.

rivermobster

Well-known member

- May 5, 2021

- 2,213

- 1,912

Just curious what an ideal temperature swing would be between the radiator inlet and outlet. My scenario is a LS1, CBR aluminum radiator with two 12” SPAL fans. Delphi computer cuts the fans in at 201 and out at 185 if I recall correctly. With the engine idling in 90° ambient air, my upper radiator fitting reads 205ish with an infrared temp gun (aluminum AN fittings upper and lower) while the lower reads about 180°. My fans run constantly once the engine reaches operating temperature in this scenario. This has lead to the occasional burned up fan relay. For reference the computer did have triggers for the fans to come on separately, but they have since both been wired together on the cooler circuit. The temp gun on the cylinder heads reads about 187~190.

As others have mentioned...

Where is your temp sensor located?

Cookie

Well-known member

- May 5, 2021

- 2,061

- 2,416

My thought, something else is wrong if you are melting pins on the relays, that is a lot of resistance.Wire (gauge), connectors and relays were all upgraded before last season and I went through two relays. The fans are new, legit brushless SPAL fans, I double checked and they’re actually 16”. I’m not feeling additional heat from the wiring or connectors, but the damn relays keep melting a pin. I do dune hard with plenty of pepper and as few breaks as I can manage. I have a windshield and a radiator that is pretty low, so maybe the cooling system is just inadequate?

Sandkist

Well-known member

- May 6, 2021

- 2,959

- 705

Those 16” fans draw 42 Amps each at 12 volts. What size relay are you using. If you are using a thermostat than your lower hose temperature should be equal to or less than the stat rating.

- Thread starter

- #12

Must have missed this, it’s in the thermostat housing/ water pump outlet side. The heater loop holes were modified, one plugged and the other has the water temp sensor.As others have mentioned...

Where is your temp sensor located?

- Thread starter

- #13

It was wired with what appeared to be Amazon relays. I have swapped both of the originals out with these that say Omron, but came in a Genuine GM baggie. We’ll see how long these last compared to the chinesenum that have melted. I can’t seem to find literature on thr amperage rating for these relays though.Those 16” fans draw 42 Amps each at 12 volts. What size relay are you using. If you are using a thermostat than your lower hose temperature should be equal to or less than the stat rating.

Jtmoney714

Well-known member

- May 6, 2021

- 972

- 866

Those mini relays are hard to find in higher amp ratings.

Rockwood

Well-known member

- May 5, 2021

- 6,389

- 8,207

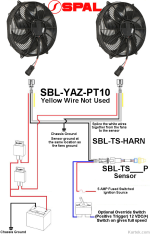

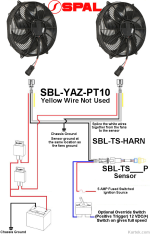

Why are you using relays with SPAL Brushless fans? Those shouldn't be on an on/off, but PWM signal from a controller. The speed should slide from barely on at 185* to full boogie at 201* if that's your scale. Wiring should be direct to battery via adequate fuse/wire (60A and 8AWG min) with the small control wire to the ECM or external controller.

Since you're running a radiator with little natural airflow, your fans are going to run a lot. So long as coolant temps are in check, this isn't a concern other than melting relays, but you also shouldn't be running relays.

Also: the bigger the difference in inlet/outlet temps, the hotter the engine is. It's counter-intuitive, but in order for there to be a large difference, the engine has to be hotter. Coolant temps in the engine are quite honestly the only thing that matters unless you're diagnosing a clog or radiator issue.

Since you're running a radiator with little natural airflow, your fans are going to run a lot. So long as coolant temps are in check, this isn't a concern other than melting relays, but you also shouldn't be running relays.

Also: the bigger the difference in inlet/outlet temps, the hotter the engine is. It's counter-intuitive, but in order for there to be a large difference, the engine has to be hotter. Coolant temps in the engine are quite honestly the only thing that matters unless you're diagnosing a clog or radiator issue.

Kraut_n_Rice

Site Sponsor

- May 9, 2021

- 3,410

- 2,695

Why are you using relays with SPAL Brushless fans? Those shouldn't be on an on/off, but PWM signal from a controller. The speed should slide from barely on at 185* to full boogie at 201* if that's your scale. Wiring should be direct to battery via adequate fuse/wire (60A and 8AWG min) with the small control wire to the ECM or external controller.

View attachment 163339

Since you're running a radiator with little natural airflow, your fans are going to run a lot. So long as coolant temps are in check, this isn't a concern other than melting relays, but you also shouldn't be running relays.

Also: the bigger the difference in inlet/outlet temps, the hotter the engine is. It's counter-intuitive, but in order for there to be a large difference, the engine has to be hotter. Coolant temps in the engine are quite honestly the only thing that matters unless you're diagnosing a clog or radiator issue.

100% this. Remove the relays and upgrade wire direct to the battery.

lincster

Well-known member

- May 5, 2021

- 893

- 712

My radiator sits down below my back seat and I have no heating issues.Wire (gauge), connectors and relays were all upgraded before last season and I went through two relays. The fans are new, legit brushless SPAL fans, I double checked and they’re actually 16”. I’m not feeling additional heat from the wiring or connectors, but the damn relays keep melting a pin. I do dune hard with plenty of pepper and as few breaks as I can manage. I have a windshield and a radiator that is pretty low, so maybe the cooling system is just inadequate?

If you really have brushless fans, they are wired wrong, as Rockwood said.

You should have a sensor in the radiator with a bung welded into the radiator.

Kraut_n_Rice

Site Sponsor

- May 9, 2021

- 3,410

- 2,695

Is the Delphi ecu used capable of PWM fan control? Or, is it energizing and deenergizing the override wire at the temps noted above?

Even if the override wire is used as "control", these fans still have a somewhat soft start.

Even if the override wire is used as "control", these fans still have a somewhat soft start.

lincster

Well-known member

- May 5, 2021

- 893

- 712

I thought brushless fans work independent of the computer?Is the Delphi ecu used capable of PWM fan control? Or, is it energizing and deenergizing the override wire at the temps noted above?

Even if the override wire is used as "control", these fans still have a somewhat soft start.

Hence why they are wired direct to battery for power and have a sensor in the radiator that detects temperature.

The only switch is an override switch wired to a switch pro or some other switch.

rivermobster

Well-known member

- May 5, 2021

- 2,213

- 1,912

Must have missed this, it’s in the thermostat housing/ water pump outlet side. The heater loop holes were modified, one plugged and the other has the water temp sensor.

See Rock wood's post?

Move the fan temp sensor to the radiator outlet hose.

When I had to do this on a customers car, I had a stainless hose coupler made, with a bung for the fan temp sensor.

These guys made it for me:

JMD Tubes

Performance products and fabrication components. We carry a wide variety of products and services, anything from mandrel bends, flanges, titanium bends and even flux capacitors.

www.jmdtubes.com