Kraut_n_Rice

Site Sponsor

- May 9, 2021

- 3,473

- 2,733

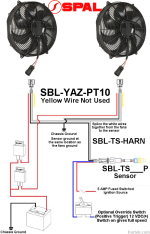

If computer has PWM outputs it can control it with a standard temp sensor input versus the Spal sensor. The Spal sensors have a narrow temperature band, and they are expensive. However, they do allow for basically a standalone install if a car was being retrofitted and didn't have the option in the computer.I thought brushless fans work independent of the computer?

Hence why they are wired direct to battery for power and have a sensor in the radiator that detects temperature.

The only switch is an override switch wired to a switch pro or some other switch.

If the computer does have PWM outputs, and you know the PWM profile of the fan motor, you can have a broader temp range controlled.

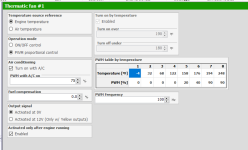

Here is a snip of PWM control in Fueltech for a fan I'm going to use. Most PWM fans don't operate at a percent less than 5, or more than 90. In this case 90% would be the signal for full blast. Some do operate on the inverse where 5% would be full blast...