@Travelah Travis...You always create BEAUTIFUL work. If I could afford you, I'd have you wiring my whole car...

The fuel pump, injectors, fans, etc...are all running through my FuelTech. I'm only using my SwitchPro for Main power (on/off), lights, radio and GPS.

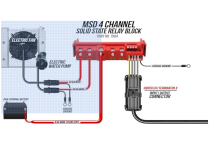

The Switch Pros handles overcurrent and relays for you. I take it the breakers are for the fuel pump, injectors, fans, etc?

Only word of advice, based on years of working on other people's shit and Navy systems some field technician bandaided for 10 years: use unique wire colors for every circuit. Not color coded ends. Not labels on the wire (though useful). Not numbers/hieroglyphs.

Unique wire colors. Finding a break in the middle of the wire somewhere, then trying to figure out which of the 87 goddamned red wires it is and where it goes, or having labels fall off or fade, or a myriad of other things makes you want to punch babies and kill kittens when the whole group is watching you diagnose a problem as the sun is setting.

Also: make sure the relay plugs are accessible in a hurry.

@Deviantduner had an issue we needed to tow him out for. Needed to have the ignition on for PS, but engine off. Disconnecting all the pumps/fans a monster turbo powerplant like his was real fun with the relay plugs buried in an access panel.

Oh, and don't solder shit. Good crimp connectors and strain relief:

If it doesn't grab the wire insulation like above, the flex point is where the wire comes out of the insulation. It will eventually fail, even with good high $ heat shrink. Ask me how I know.

I've converted all of my wiring over with these crimps and connectors:

(NOTE: the above link pictures the correct connectors, but doesn't include them. The more expensive kits with connectors included are barrel only, not strain relief)

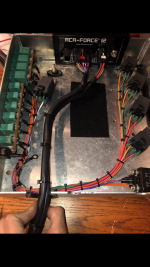

And has worked well so far. The crimper is pure Chinesium, but is accurate enough for our work and has lasted through multiple cars. Here's a crimp I did as part of a relay harness: