J Alper

Site Sponsor

- Apr 30, 2021

- 1,851

- 1,606

Got a new to me Lathe from Mark @allenoffroad

Mine is wired for 440V,

Got a 3 Phase Converter, from North American Rotary, all hooked up,

Checked all legs of 3 phase, its making 240V on all 3 legs,

The Transformer was just buzzing, Moved one of the wires from 440V to the 220V on the buss bar, now the light turns on the relay kicks on, but the Contactors are making a loud buzzing noise when you try to flip the lever for the motor to kick in,

Pretty sure i need to move or add another wire from the transformer,

NOT sure how to use a multimeter on this type of equipment safely, my use of a multimeter is -- checking 110V, checking 220V, checking the leg of 3 phase with two legs at a time, and checking 12V-DC,

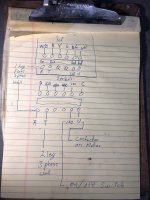

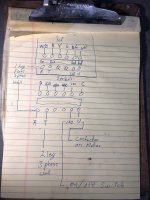

Added some pics of what i am working on

Mine is wired for 440V,

Got a 3 Phase Converter, from North American Rotary, all hooked up,

Checked all legs of 3 phase, its making 240V on all 3 legs,

The Transformer was just buzzing, Moved one of the wires from 440V to the 220V on the buss bar, now the light turns on the relay kicks on, but the Contactors are making a loud buzzing noise when you try to flip the lever for the motor to kick in,

Pretty sure i need to move or add another wire from the transformer,

NOT sure how to use a multimeter on this type of equipment safely, my use of a multimeter is -- checking 110V, checking 220V, checking the leg of 3 phase with two legs at a time, and checking 12V-DC,

Added some pics of what i am working on

Last edited by a moderator: