- Thread starter

- #1,021

onanysunday

Well-known member

- May 7, 2021

- 3,873

- 3,526

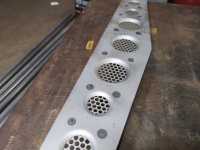

8 straight days and one more to go. Then I'm headed to the mountains. It has been wicked hot in the shop. Going a couple extra tenths looser on the guides with boost. Getting closer on the steering system. A little overkill on how heavy duty everything is but certainly won't have to worry about it. Might be able to turn the tires with the steering wheel tomorrow if I can get that front bracket for the lower v dog box built. And if my two couplers that I need come in.