Kraut_n_Rice

Site Sponsor

- May 9, 2021

- 3,453

- 2,722

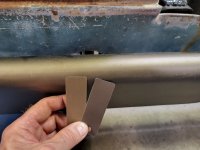

Notice how the shafts are offset a bit. Picture a planetary gear set in an auto trans, but with only one planet and the ring gear....no sun gear. The one that is centered is the ring gear, the offset one is the planet. This is how they can also offer different ratios.