DeepBusch69

Active member

- May 6, 2021

- 149

- 124

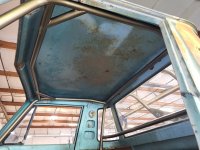

That was a big time challenge making those rally style corner pieces. Spent about an hour with PVC first. The two copes were not exactly lined up and had to rotate the tube about 3/8 on one end. Getting closer on this cage. Tomorrow I can bolt it up in place and the only thing left is that front crossbar at your feet/knees. I am sore from all the twisting and turning to try TIG weld this whole thing. Certainly gaining some skill along the way. Fun project. I did find a real nice set of C1 Corvette visors with the little brackets. Hopefully they will work with some brackets. My bottom plates for the roll bar are supposed to be .125 to pass tech. The plates I have are only .115. Miniscule difference but I have to decide if I'm going to buy more steel and make this tech Worthy.

View attachment 110501

View attachment 110502

View attachment 110503

View attachment 110504

View attachment 110505

View attachment 110506

View attachment 110507

View attachment 110508

Great idea using PVC for your mock up parts