- Thread starter

- #381

onanysunday

Well-known member

- May 7, 2021

- 3,764

- 3,449

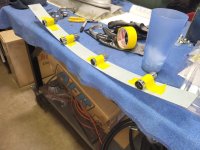

I also have the steering wheel and seat moved towards the center of the truck about 3.5 in. Just feels like it will be a good spot for it and I'm not sure what kind of angled down bar we're going to have near the door as part of the cage.