Jammer75

Well-known member

- May 5, 2021

- 552

- 509

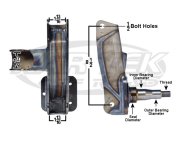

I bent my spindle which is the one that has the long blot that goes down trough the spindle itself(see pic). They measure 8.5" from the middle of the top heim to the middle of the lower heim. I have a pair of what seems to be Tatum spindles of the same sort although they only measure about 6 3/4" (why shorter?) from middle of top to middle of bottom heim. I assume I could use these as long as I extend the top heim out to make up for the angle difference..??

The more common spindle is the https://www.appletreeauto.com/a-arm-spindles-combo-bearing-left-and-right/?gclid=CjwKCAiA9tyQBhAIEiwA6tdCrO92Bqnb5UMtIj-o1UYLFW6Yl3pVwT45_lllAAYabZ0uK_05MqVwKBoCt1QQAvD_BwE which all of these styles seemed to be 8.5" from center to center on heim. Should I go with a new set like these (are the kartek ones better? all seem to be tig welded..?)

Should I stick with the "Tatum" ones and adjust the top heim out to match the wheel angle of the 8.5"..?

The more common spindle is the https://www.appletreeauto.com/a-arm-spindles-combo-bearing-left-and-right/?gclid=CjwKCAiA9tyQBhAIEiwA6tdCrO92Bqnb5UMtIj-o1UYLFW6Yl3pVwT45_lllAAYabZ0uK_05MqVwKBoCt1QQAvD_BwE which all of these styles seemed to be 8.5" from center to center on heim. Should I go with a new set like these (are the kartek ones better? all seem to be tig welded..?)

Should I stick with the "Tatum" ones and adjust the top heim out to match the wheel angle of the 8.5"..?