HydroPower

Active member

- May 10, 2021

- 106

- 60

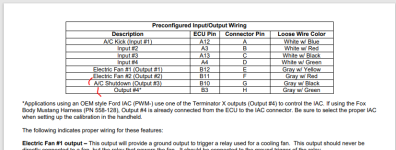

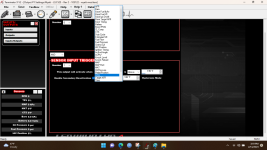

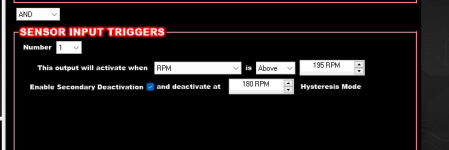

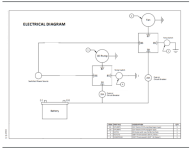

Picked up a new car recently and it has an external engine oil cooler as well as a trans pump and trans cooler and i have 3 switches on the dash, one to turn on each of the functions. I just ordered everything to upgrade the car to a new Holley Term X ECU and was wondering if there was a better way to power the coolers and pump other than keeping them on a switch. Im also going to install a switch pros so wondering if i need to keep switches or put the coolers on temperature controlled switches that will turn them on automatically.

How is everyone setting these types of features up?

How is everyone setting these types of features up?