DeepBusch69

Active member

- May 6, 2021

- 150

- 124

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Depends on the master cylinder but it can bend the fingers on the pressure plateNever thought this was an issue. won’t pressing the pedal “too far” just compress the spring and piston then stop? What damage can be caused? Xtra pressure on the piston or the housing? Just curious.

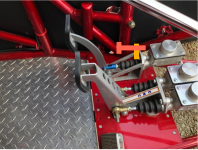

I was wanting to add a stop or limit for the clutch pedal so I don't push it too far a damage it. I have some standard CNC pedals. Any good ideas out there, thanks

View attachment 11546

Me either, except on a busa, bike motor, they will shove the clutch rod through the engine case if not careful.Never thought this was an issue. won’t pressing the pedal “too far” just compress the spring and piston then stop? What damage can be caused? Xtra pressure on the piston or the housing? Just curious.

Nice way to do it on swing pedals, maybe put a rubber pad on the stop - its nicedont have a clutch in my car, but i did make one for my brake pedal, its welded to chassis and stops the pedal. i made it so it stops at the point i have no leg left to push the pedal any farther and have the master linkage set so the full travel of the master is utilized in the pedal travel i have set for my foot.

View attachment 11679

so far its never come close to hitting the stop thankfully. if it does hit the stop then i got problems! lolNice way to do it on swing pedals, maybe put a rubber pad on the stop - its nice

so far its never come close to hitting the stop thankfully. if it does hit the stop then i got problems! lol

I fixed alot of Centerforce's on a number hot street cars when people would over center the clutch spring at really high RPM like an 8000 RPM shift, the spring would be on the other side so the "cone" would actually hold the clutch depressed and it would not engage unless you let off the throttle and RPM came way down. A simple clutch stop and problem solved.Two things can happen without a pedal stop:

1. Over extend throw out bearing into pressure plate fingers, which can pull the bearing off the fork in a typical VW style release shaft/fork mechanism, or push the piston out of the housing on an Albins/Weddle HV and new design S4D/S5D Chevy bell housing with hydraulic slave cylinders built inside the bell housing. Either issue requires pulling the engine to fix.

2. On Weddle/Centerforce clutches, throw bearings can interfere with centrifugal weights on pressure plate, pulling the bearing off the forks. Or over extend the fingers into the clutch discs behind and interfere with drive pins on discs.