I havnt done much welding. Please teach me anything you find relevant. Even if it seems simple and obvious, it might be new to me.

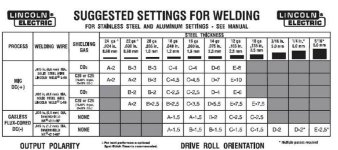

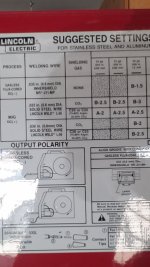

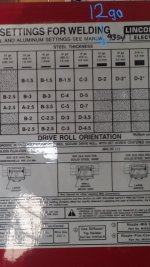

Want to turn this bedframe into a television mount. It measures to be 0.100" thick so im guessing that is 12 gauge according to the chart on the welder.

Pretty sure i have 0.023" wire in there and its the 75% argon mix. According to the chart 14 gauge is the thickest it recommends. I know it can go thicker because we used it to weld a U shape piece of rebar onto a chunk of metal that must be 1/2" thick. Im looking for advice you might have when using smaller 120v welders to do thicker stuff.

I have a bunch of questions but will try to keep it short.

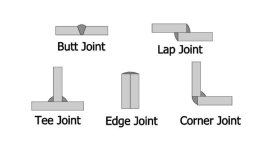

1. When i lay a piece of 0.100" metal perpendicular to another identical piece and then weld a bead along the side how do you calculate the thickness for the welding chart? Its not a butt joint so the metal is no longer 0.100" in total. But im welding along the side so its also not doubled to 0.200".

2. What settings would you choose for the welder posted and the metal is 0.100" thick?

Want to turn this bedframe into a television mount. It measures to be 0.100" thick so im guessing that is 12 gauge according to the chart on the welder.

Pretty sure i have 0.023" wire in there and its the 75% argon mix. According to the chart 14 gauge is the thickest it recommends. I know it can go thicker because we used it to weld a U shape piece of rebar onto a chunk of metal that must be 1/2" thick. Im looking for advice you might have when using smaller 120v welders to do thicker stuff.

I have a bunch of questions but will try to keep it short.

1. When i lay a piece of 0.100" metal perpendicular to another identical piece and then weld a bead along the side how do you calculate the thickness for the welding chart? Its not a butt joint so the metal is no longer 0.100" in total. But im welding along the side so its also not doubled to 0.200".

2. What settings would you choose for the welder posted and the metal is 0.100" thick?