onanysunday

Well-known member

- May 7, 2021

- 3,752

- 3,445

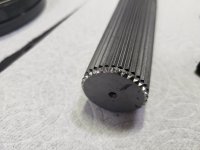

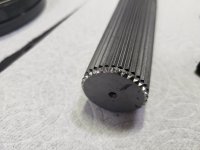

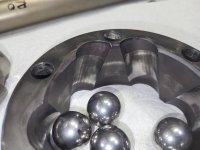

So when I put this thing together 3 years ago I thought I had measured twice and cut once. Lol. Anyway the car has been running with only a quarter inch axle end play. Kartek had told me that is actually okay but I understand it is still close. My uniballs are already starting to get a little loose even with seals and grease in them. I would say the trailing arm moves back and forth maybe .010 to .015. So not much but starting to get a slight amount of play. One side apart and so far so good other than when the axle drops down against the upper clip it is rubbing on the micro stub. I did have to file each tooth to slide the outer CV off. I'm going to cut one quarter inch off one end and regroove it. I assume cut it off the inside end of the axle but not sure if that will make any difference. I don't see how this is going to be an issue long-term but wondering if it is normal.