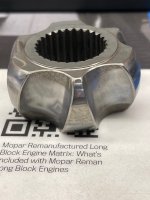

Might as well go down this road, I'll start with some show and tell. I've got a 4 seater, stock LS3, HV-24, 33 Blasters and it probably weights 2500-2600lbs. The ass end is 95" wide measured outside of tire to outside of tire, I have 31" 300M Tatum axles and I use Tatum midboard hubs. I also use 930 cvs. I can destroy cheap EMPI stars in less than a season, so I switched over to Fortin 300M stars and cages 3 seasons ago and have had very good luck with them. I didn't do a complete teardown and regrease last season I only pulled the boots back and squirted in some grease a few times, this year I took them apart and cleaned them thoroughly in the solvent tank. Luckily, I only had 1 star with some pitting where the ball apparently applies most of it's torque. At $91 for a new Fortin 300M star from Kartek I'll happily continue to use my 930 gear. It's strange that only 1 of them was pitted but I'm not complaining lol.

Now with that said, our new frame made with 1 3/4 x .120 4130 may be a bit heavier when it gets put into service and may cause some faster wear on the cv stars, but we will cross that bridge when we get to it. The swap to 934 midboards ain't cheap, I'm not even sure that's the route I'd go. I would be inclined to install outboard hubs and be done with it, however I can buy a lot of 300M stars for the $10,000 it would cost to install outboards and axles (that's a reasonable estimate taking into consideration all of my fabrication and modification is done in house) not to mention the added wear on the transaxle due to the increase in rotating mass. Why do I talk about outboards you ask? Imagine how long a cv would last living it's life at only 10 or 12 degrees of angle...

Oh and the grease, I've been using straight Swepco moly grease as it does just as good of a job as the mixes did. It seems the Bel Ray part of the mix caked up everywhere but in the joint and did nothing special. Currently I've got a couple of tubes of John Deere moly grease I'm going to use, IMO it's all moly grease in different tubes but that's a different thread haha.

Tell us about your car and cv stories, and I wasn't looking to discuss adapters of any kind.

Now with that said, our new frame made with 1 3/4 x .120 4130 may be a bit heavier when it gets put into service and may cause some faster wear on the cv stars, but we will cross that bridge when we get to it. The swap to 934 midboards ain't cheap, I'm not even sure that's the route I'd go. I would be inclined to install outboard hubs and be done with it, however I can buy a lot of 300M stars for the $10,000 it would cost to install outboards and axles (that's a reasonable estimate taking into consideration all of my fabrication and modification is done in house) not to mention the added wear on the transaxle due to the increase in rotating mass. Why do I talk about outboards you ask? Imagine how long a cv would last living it's life at only 10 or 12 degrees of angle...

Oh and the grease, I've been using straight Swepco moly grease as it does just as good of a job as the mixes did. It seems the Bel Ray part of the mix caked up everywhere but in the joint and did nothing special. Currently I've got a couple of tubes of John Deere moly grease I'm going to use, IMO it's all moly grease in different tubes but that's a different thread haha.

Tell us about your car and cv stories, and I wasn't looking to discuss adapters of any kind.

Last edited by a moderator: