John@Outfront

Forum Moderator

- Apr 30, 2021

- 1,354

- 1,818

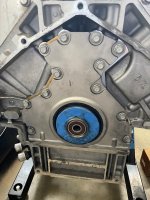

Hey guys I don't usually work on these motors but I'm doing a rear main seal and want to remove and reseal the large plate at back of motor that holds the rear main seal. its in a 15 passenger van i have no hoist to raise this thing so my guy is doing it on the ground and only pulled the tranny back 6"

Question can that rear plate be removed and resealed with out removing the oil pan or is there a reason i could not?

its a cast aluminum pan

Question can that rear plate be removed and resealed with out removing the oil pan or is there a reason i could not?

its a cast aluminum pan